Description

Transparent Level Gauge with Mica Shields for Good Corrosion Protection

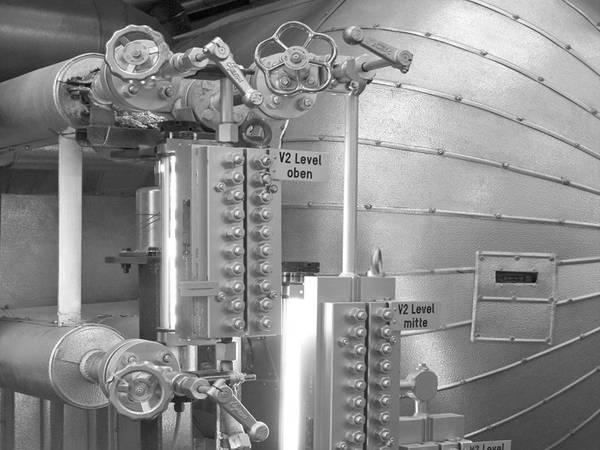

Transparent level gauge is designed to indicate the liquid level as the result of the different transparency of liquid and air.

It consists of a chamber and two transparent glasses mounted on the front and back of the chamber. As the transparent level gauge works, the light enters from the back of the transparent level gauge, illuminating the chamber between two glasses. As a result, the operator can observe the liquid level from the front of the transparent level gauge.

It not only allows operators to observe the liquid level changes directly under high temperature and high pressure conditions, but also enables operators to observe the liquid color changes as well as the total and interface liquid level changes. In addition, Mica shields are provided to protect the glass surfaces from corrosive action of the process fluid, thereby allowing the transparent level gauge to operate in corrosive conditions.

Transparent level gauges are widely used in the liquid level measurement of heavy oil, residual oil and pure ammonia tanks in the fields of petroleum, chemical, power, metallurgy, etc.

A transparent level gauge and a transparent gauge glass

Transparent liquid level

Features

Corrosion resistant. Mica shields are placed between the transparent gauge glass and the chamber to protect glasses from the corrosion of hot alkali or acid solutions, meanwhile, the lifespan of the transparent gauge is extended accordingly.

Direct reading. The transparent level gauge allows operators to observe the interface and total liquid level changes as well as the liquid color changes directly under the light illumination.

Simple structure & easy maintenance.

High temperature and high pressure resistant. It can provide a long-term, stable liquid level measurement under high temperature and high-pressure conditions.

Self-closing function. The steel ball inside the needle valve at both ends of the transparent level gauge functions as a check valve. In the event of the glass breaking, the steel ball will automatically close the liquid channel under pressure to prevent the liquid from flowing out, thereby reducing economic losses and avoiding casualties.

Specification of Transparent Level Gauges

Center to center distance 300–3000 mm

Operating Pressure 0.2–10 MPa

Operating Temperature -20 °C to +450 °C

Steel Ball Self-Closing Pressure 0.2 MPa

Chamber Material Carbon steel or stainless steel

Gauge Glass Material Borosilicate glass, aluminosilicate glass

Way of Observation Visual inspection

Way of Connection Flange connection

Structure